- The design would have to benefit the bees.

- It would have to benefit beekeepers.

- It would have to benefit science.

So how do bees and beekeepers benefit from the Bee Barrel?

Protection from the Environment

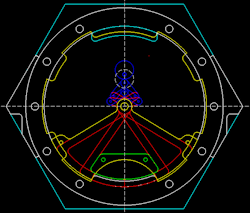

For starters, the minimum distance between the inside and outside edges of each barrel ring is twice the thickness of a standard hive box made of 3/4" pine. (a.k.a 1x or 'one-by') and each ring is uniquely designed with a hollow core. This provides a dead air space which increases the insulation factor of the ring and reducing the overall weight of the barrel making it lighter than its traditional counterpart. These advantages help protect the colony in extreme climate conditions and aid the bees in regulating the temperature and humidity inside the hive cavity.

Minimizes Stress and Eliminates Damage

The ring's width as well as its thickness contributes to a stronger frame for holding the foundation plate. The consequent rigidity prevents warpage which encourages the bees to maintain the proper cell depth and results in virtually no burr or cross comb. In other words, the bees do not 'bind' or 'glue' the rings together by bridging the space between the rings like they do in traditional boxes. The rings are so precise that there are very few gaps to be filled with propolis which means the rings will come apart quite easily during inspection. All of this contributes to less damage to the honeycomb which results in reduced stress on the bees and less resource that they have to commit to repairing damage.

The stronger ring also eliminates frame breakage. To put that in perspective, a single broken frame in a ten-frame super equates to 10% breakage for the beekeeper. Now multiply that by several supers and you start to see how much time and money is saved by eliminating frame and box failure.

Increased Productivity

The Bee Barrel is naturally lighter than wooden supers and can be easily transported and managed. Full hives are heavy so less net weight means less effort to work with the hive.

And Bee Scientific is currently developing less expensive and more efficient ways to extract honey:

For the hobbyist with one or two hives the process will be as easy as extracting into a five gallon bucket and placing the extractor on a shelf when finished. No more $400.00 extractors to buy or places to find to store them when not in use.

For the commercial beekeeper it's matter of automation. Extraction on steroids. Since the patents for these designs have not yet been filed we are unable to say much more than how anxious we are to make these devices available. But think pinewood derby. Yeah a little weird but imagine placing the barrel on a track that would allow it to slide through a process that completely automates the extraction process. You place it on the rail at the front and pick it up at the back - completely clean, extracted and re-assembled!